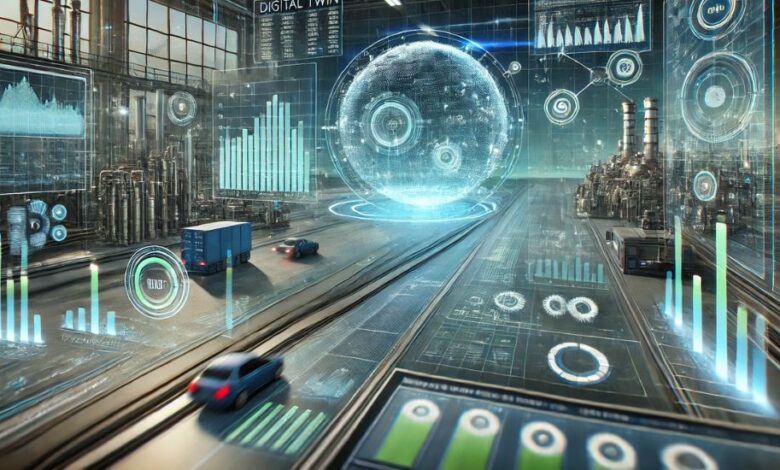

Stream Data Digital Twin: A Revolution in Real-Time Monitoring

In today’s rapidly evolving digital landscape, the concept of the “stream data digital twin” is making waves across various industries. This innovative technology is reshaping how businesses operate, manage resources, and interact with their environment. At its core, the stream data digital twin combines the digital twin model with real-time data streams, offering unparalleled insights and optimization capabilities.

In this article by USA Magzines, we will explore what a stream data digital twin is, how it works, and why it’s becoming an essential tool for industries that rely on real-time data processing. By diving into its components, benefits, and practical applications, we aim to uncover why the stream data digital twin is at the forefront of the digital revolution.

What is a Stream Data Digital Twin?

The term “digital twin” refers to a virtual representation of a physical entity, such as machinery, equipment, or even whole ecosystems. A digital twin allows companies to simulate and analyze their assets digitally before making any physical changes. However, when coupled with stream data, this concept takes on a new level of sophistication.

A stream data digital twin continuously receives live data from physical objects or environments. This real-time data flow provides an up-to-date view of the digital twin, allowing it to reflect real-world conditions dynamically. Through this process, industries can monitor and optimize their operations with precision, addressing issues in real time, predicting maintenance needs, and improving overall performance.

Key Components of Stream Data Digital Twin

To understand the power of stream data digital twins, it is essential to break down their core components:

- Physical Asset or System: The foundation of any digital twin is the physical entity it represents. This could be anything from a single machine in a factory to an entire smart city system.

- Sensors and IoT Devices: Real-time data streams come from a network of connected sensors and Internet of Things (IoT) devices. These devices capture data related to the physical entity, such as temperature, pressure, movement, or performance metrics.

- Data Processing and Analytics: Stream data is processed and analyzed using advanced analytics tools. This step is crucial for transforming raw data into actionable insights, enabling predictive maintenance and performance optimization.

- Digital Twin Model: The digital twin itself is a sophisticated, data-driven model that simulates the behavior and condition of the physical asset in real time. By continuously updating with live data, the model mirrors the real-world entity with stunning accuracy.

How Stream Data Digital Twin Works

The operation of a stream data digital twin revolves around the continuous flow of information. Imagine a factory where hundreds of machines are connected to a central monitoring system. Each machine has sensors that report real-time data about its performance, temperature, and output. This information is then transmitted to the digital twin, which processes the data and mirrors the factory’s physical state in the digital space.

As conditions in the real world change, the digital twin updates its model accordingly. This constant feedback loop ensures that the virtual model is always up-to-date, offering a real-time snapshot of the physical world. This capability allows companies to detect potential issues before they become critical, optimize operational efficiency, and even simulate different scenarios to test outcomes before implementation.

Benefits of Stream Data Digital Twin

The stream data digital twin offers numerous benefits that are transforming the way industries approach data-driven decision-making:

- Real-Time Monitoring: The most significant advantage of the stream data digital twin is its ability to provide real-time monitoring of physical assets. By continuously receiving live data, businesses can quickly identify problems, reduce downtime, and improve overall performance.

- Predictive Maintenance: With the help of real-time data streams, digital twins can forecast when a machine or system might need maintenance. This predictive approach helps avoid unexpected failures and extends the lifespan of equipment.

- Operational Efficiency: Stream data digital twins enable businesses to simulate and optimize various operational processes. Whether it’s managing energy consumption, reducing waste, or optimizing logistics, the real-time feedback from the digital twin allows for more informed decisions.

- Enhanced Decision-Making: By simulating scenarios based on real-time data, companies can test different strategies and solutions before implementing them in the real world. This approach reduces risks and improves the effectiveness of business decisions.

- Cost Savings: Stream data digital twins lead to significant cost savings by improving efficiency, reducing downtime, and preventing costly repairs through predictive maintenance.

Applications of Stream Data Digital Twin

The potential applications of the stream data digital twin span multiple industries, each benefiting from its real-time insights and optimization capabilities. Here are some notable examples:

Manufacturing

In the manufacturing sector, stream data digital twins play a vital role in monitoring machinery, improving production lines, and optimizing resource use. By analyzing real-time data from the factory floor, manufacturers can quickly adjust their processes to increase efficiency and reduce operational costs.

Healthcare

Stream data digital twins are transforming healthcare by offering real-time monitoring of patients and medical equipment. For instance, digital twins can simulate the behavior of medical devices, predict maintenance needs, and ensure they are always functioning optimally. Moreover, patient care can be enhanced through real-time monitoring of vital signs and health data, allowing for personalized treatments.

Smart Cities

In urban planning, stream data digital twins are used to monitor city infrastructure, from traffic systems to energy grids. By analyzing data streams from these interconnected systems, city planners can optimize traffic flow, reduce energy consumption, and create more sustainable urban environments.

Energy Sector

The energy industry relies heavily on stream data digital twins to monitor power plants, oil rigs, and renewable energy installations. By using real-time data, companies can optimize energy production, predict maintenance issues, and reduce the environmental impact of their operations.

Challenges of Stream Data Digital Twin Implementation

While stream data digital twins offer numerous benefits, implementing this technology comes with its own set of challenges:

- Data Integration: Collecting and integrating data from a variety of sensors and systems can be complex, especially in industries with legacy systems that do not easily support modern data streams.

- Cybersecurity Concerns: The continuous flow of data between physical assets and their digital twins presents potential cybersecurity risks. Protecting this data from cyber threats is crucial to ensuring the safety and integrity of both the digital twin and the physical entity it represents.

- Cost of Implementation: Setting up a stream data digital twin infrastructure can be costly, particularly for small to medium-sized businesses. However, the long-term benefits often outweigh the initial investment.

The Future of Stream Data Digital Twin

As industries continue to digitize their operations, the use of stream data digital twins is expected to grow exponentially. From predictive maintenance to optimizing entire supply chains, this technology is poised to become a cornerstone of the modern digital economy. The integration of artificial intelligence and machine learning with stream data digital twins will further enhance their ability to analyze data and predict outcomes with even greater accuracy.

In conclusion, the stream data digital twin is an innovative approach that combines real-time data streams with digital twin models to offer a highly accurate and dynamic representation of physical assets. As companies like those featured in USA Magzines explore new ways to leverage this technology, we can expect even more transformative changes in the way industries operate and interact with the world around them.